Startseite » Produkte » Ball Valves » PROKOSCH Flanged Ball Valve, Model 400

Available in material combinations of aluminum, cast iron and stainless steel.

You can download the data sheet here.

PROKOSCH ball valves are suitable for granulated and powdered media as well as neutral liquids, suspensions and gases. They are characterised by the use of fewer individual parts and space-saving elements as well as easy switchability and long service life.

The free passage reduces flow resistance to a minimum and the ball bearing on both sides reduces wear on the ball seats and ensures a uniformly low switching torque over the entire pressure range.

Thanks to a sensible modular principle, the ball valve is easily configurable and our standard designs and options allow a wide range of applications. Due to the fact that the ball valve does not have its own ignition source, it can also be configured for safe use in various ATEX applications.

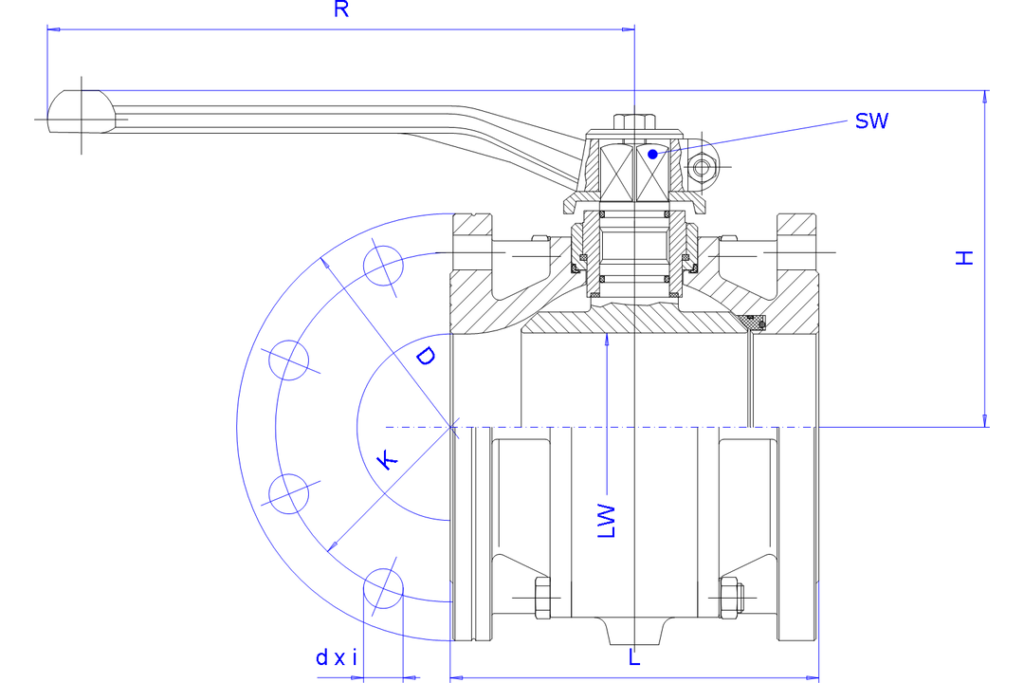

| DN | PN | LW | L / H | D / K | d x i |

| 50 (2″) | 16 | 50 | 144 / 130 | 165 / 125 | 18 x 4 |

| 65 (2½”) | 16 | 64 | 163 / 140 | 185 / 145 | 18 x 4 |

| 80 (3″) | 16 | 78 | 180 / 150 | 200 / 160 | 18 x 8 |

| 100 (4″) | 16 | 97 | 200 / 175 | 220 / 180 | 18 x 8 |

| 125 (5″) | 16 | 122 | 200 / 200 | 250 / 210 | 18 x 8 |

| 150 (6″) | 16 | 150 | 350 / 250 | 285 / 240 | 22 x 8 |

Please download data sheet for detailed dimensions and weights.

Product configuration – most applications are covered by our standard variations supplemented with a selection of options to suit the application. Furthermore, we offer customised special designs when the applicaiton requiremenst exceed our standard variations and options.

| Standardausführungen | Code |

| Graugussgehäuse mit Hartverchromter Graugusskugel. Spezialgekammerte Sitze aus PTFE mit FKM O-Ringe | 1 |

| Graugussgehäuse mit Hartverchromter Graugusskugel. O-Ring-angefederte Sitze aus PTFE mit FKM O-Ringe | 2 |

| Aluminiumgehäuse mit Hartverchromter Graugusskugel. Spezialgekammerte Sitze aus PTFE mit FKM O-Ringe | 3 |

| Aluminiumgehäuse mit Hartverchromter Graugusskugel. O-Ring-angefederte Sitze aus PTFE mit FKM O-Ringe | 4 |

| Gehäuse und Kugel aus Aluminium. O-Ring-angefederte Sitze aus PTFE mit FKM O-Ringe | 5 |

| Graugussgehäuse mit Kugel aus Edelstahl. Spezialgekammerte Sitze aus PTFE mit FKM O-Ringe | 6 |

| Graugussgehäuse mit Kugel aus Edelstahl. O-Ring-angefederte Sitze aus PTFE mit FKM O-Ringe | 7 |

| Aluminiumgehäuse mit Kugel aus Edelstahl. Spezialgekammerte Sitze aus PTFE mit FKM O-Ringe | 8 |

| Aluminiumgehäuse mit Kugel aus Edelstahl. O-Ring-angefederte Sitze aus PTFE mit FKM O-Ringe | 9 |

| Graugussgehäuse mit Borierter Edelstahlkugel. Borierte Edeltahlsitze mit FKM O-Ringe | 10 |

Sonstige Materialkombinationen wie z.B. komplett Edelstahl sind auf Anfrage erhältlich.

| Kugelabdichtung | empfohlene Anwendung |

| PROKOSCH PTFE O-Ring angefedert | Feststoffe, Suspensionen und Flüssigkeiten |

| PROKOSCH UHMWPE O-Ring angefedert | abrasivere Feststoffe und Suspensionen |

| PROKOSCH Metall-O-Ring angefedert | abrasive und adhäsive Feststoffe, Mediendicht |

| PROKOSCH Spezialgekammert | Gase und Flüssigkeiten, hohe Fließgeschwindigkeiten |

| PROKOSCH Verstopfungsfrei4) | einseitige Abdichtung mit freiem Auslauf, Mediendicht |

| Top Assembly | Code |

| Standard, with stop washer and hand lever | – |

| Bare shaft, with stop washer (without hand lever) | /OH |

| Prepared for actuator assembly, bare shaft with drilled top flange | /SO |

| Options | Code |

| Anti clogging design, seated only upstream with aerodynamic open downstream | /FA |

| Flushing port, a 1/2″ threaded hole for flushing on one side of the ball valve | /SB |

| Anti-static-device, enabling the dissipation and inhibition of electrostatic buildup | /AS |

| Lock-out-device, a valve can be locked in place by a mechanical locking device | /LO |

| E-PTFE seats, for increased conductivity for anti-static applications | (E-PTFE) |

| UHMWPE seats, alternative to PTFE seats for increased wear resistance | (UHMWPE) |

| FKM o-rings, alternative to NBR o-rings of a standard design | -FKM |

| FEP o-rings, alternative to the o-rings of a standard design | -FEP |

| Protective coating in addition to priming the cast iron bodied valves | -RAL# |

All ball valves are manufactured in our factory in Germany. Our trained employees and our ISO9001 certified quality management system ensure the high and consistent quality of our products. Furthermore, factory certificates according to EN 10204 2.2 and 3.1 are available on request.

Order Code: ////

Examples: 400/65/4/FA/SB, or 400/100/9/SO/FA/AS (E-PTFE) -RAL5019

1) NBR O-Rings -20°C, FKM O-Rings -15°C, Low temperature application -40°C with Silicone(FEP) O-Rings; 2) Higher temperature range +180°C with PTFE Seats and FKM O-Rings; 3) High temperature applications 230°C only with stainless-steel seats and FKM O-Rings; 4) The /FA anti-clogging design is available for all O-Ring tensioned seat types; 5) hard chrome plated and polished; 6) Aluminium balls available for DN40 and DN50 other sizes upon request; 7) borated for increased wear resistance, the seats are fitted with FKM O-Rings; *) DN125 optionally available with 600mm hand lever.

Do you have questions about a specific product?

Prokosch – Pumpen und Armaturen GmbH

In der Breitwiese 9, 76684 Östringen

Germany

© Prokosch – Pumpen und Armaturen GmbH 6/2023