Based on our many years of experience and our technical know-how, we consult our customers in challenging control and shut-off applications.

In close cooperation with our customers, we develop technically and economically suitable solutions that meet the case-specific media, operating and environmental requirements. Should a customer application require certain special functions, we are happy to develop a customized solution that goes beyond the functions already available and is based on our modular design and our standard functions and options.

Production and assembly take place “under one roof” in our main plant. Our high vertical range of manufacture as well as a selected supplier base ensure quality and delivery capability. This allows us to achieve a flexibility that is unparalleled today. In addition, we can offer a wide range of valves and pumps “from one source” through our extensive procurement channels and in cooperation with our system suppliers.

The documentation for our products, consisting of standard data sheet, operating instructions with declaration of conformity, is available online.

Individualized product-specific data sheets with spare parts lists, 3D models as well as third-party documentation for accessories are available in connection with an order or a project quotation, or on request.

Our delivery condition is EXW or in case of export FCA our factory address In der Breitwiese 9, 76684 Östringen, Germany.

Within Germany and the EU, the shipment of the goods is usually organized in cooperation with our logistics partners and invoiced by us. Depending on the weight, the delivery is made by parcel service or freight forwarder.

Deliveries to third countries (export) are usually to be organized by the customer. On request, we can organize the transport to the port of destination (CIF or CPT). Shipping documents, e.g. export accompanying documents, certificates of origin and movement certificates, are provided by us.

Our high manufacturing standard allows excellent repairability of our products.

Our valves can be serviced without special tools. In addition to parts subject to normal wear, every single part is available as a spare part and can be replaced. Factory repairs and revisions are available upon request. Please refer to our material return policy to ensure quick and efficient turnaround.

Quality you can rely on

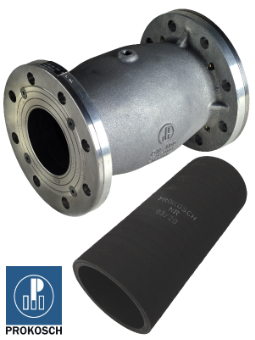

We are your specialist and partner for ball valves, pinch valves and flow accelerators made of aluminum, cast iron and stainless steel, as well as other valves and pumps.

Quality you can rely on

We are your specialist and partner for ball valves, pinch valves and flow accelerators made of aluminum, cast iron and stainless steel, as well as other valves and pumps.

PROKOSCH ball valves are an excellent choice for handling gases and neutral liquids as well as bulk solids – especially for silos, loading and unloading stations, tankers and silo trucks, as well as applications in industry, petrochemistry, feed and food production, agriculture and municipal engineering.

Our ball valves have bearings on both sides, which in combination with our proven seal design ensure reliable operation and long service life.

The valves are either manually operated or can be equipped with pneumatic or electric actuators. Special accessories for use in potentially explosive atmospheres (ATEX) are available.

PROKOSCH ring nozzles are used in the pneumatic conveying of bulk materials. Their optimized design ensures ideal flow conditions and reduced wear of the nozzle body.

They are available in both cast iron and stainless steel. Standard connections for screwing into the pipeline or flange connections or a combination to suit the installation situation.

Our standardized design and high manufacturing standards ensure long service life – only a few parts subject to application-related wear need to be replaced periodically.

All PROKOSCH ball valves and pinch valves can be automated without great effort. The design is either according to customer specifications, or you can use our proven PROKontrol(TM) standard solutions for automation.

Available are normal and fast switching electric rotary actuators as well as single and double acting pneumatic rotary actuators. Actuators are sized to suit the application and equipped with suitable pilot valves and limit switch boxes, depending on customer requirements. Pinch valves are predominantly equipped with an electro-pneumatic control system.

Due to our know-how in a wide range of applications and media, you can rely on our expertise in selecting a suitable automation package.

Prokosch – Pumpen und Armaturen GmbH

In der Breitwiese 9, 76684 Östringen

Germany

© Prokosch – Pumpen und Armaturen GmbH 6/2023